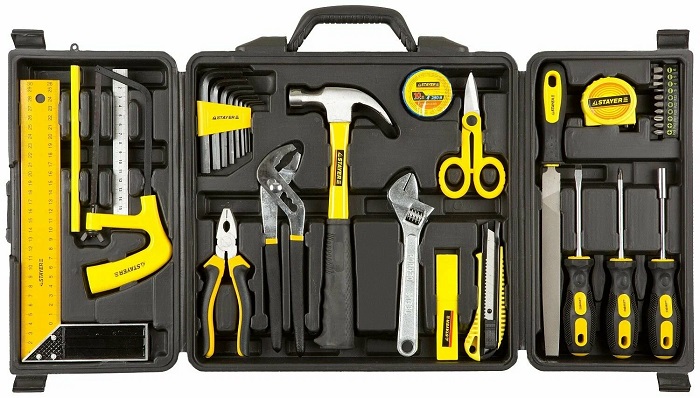

Homemade GlowForge equipment for laser cutting works using computer control and 3D CAD software. You make a 3D object model, and then the equipment cuts the part with a laser.

Laser cutter is large enough, but it can be placed on the usual table and use as a 3D printer. Like 3D printing, the device requires a 3D model which it applies to the object. Only unlike a printer, Glowforge laser cutting equipment cuts out a part, not prints it. Moreover, it can cut out an object from paper, fabric, wood, acrylic, leather, linoleum and some types of plastics. However, the thickness of the material must not exceed a quarter of an inch. You can also use glass or metal, but the equipment will engrave these materials instead of cutting them.

At the moment, a quarter of an inch is the maximum thickness that the cutter can afford. But manufacturers are confident that in a couple of years they will be able to set up the equipment in such a way that it will be possible to cut full-fledged home furniture (probably prefabricated) on it from 3D models downloaded from the Internet.

Glowforge laser cutter will be available for purchase in December. Estimated cost $2,500.

Leave a Reply